Rainy season is a challenging time for electric pallet jack. The increased moisture can cause various types of damage to the equipment, which could eventually lead to costly repairs or replacements. That's why it's crucial to take care of your pallet jack during this season. In this blog post, we'll provide you with practical tips on how to maintain your pallet truck in rainy weather conditions. Follow these steps and ensure that your equipment stays in top shape, no matter the forecast!

Why is it important to maintain your electric pallet jack in the rainy season?

Maintaining your pallet jack in the rainy season is essential to ensure its longevity and efficiency. The moisture from the rain can affect the various parts of your equipment, causing rust, corrosion, and other forms of damage that may lead to costly repairs.

One critical aspect of maintaining your electric pallet jack during this time is to keep it dry. Moisture accumulation on your equipment can cause electrical systems failure or seep into mechanical components such as bearings and gears, leading to further damage.

Additionally, keeping up with regular maintenance checks will help identify any potential issues early on before they become more significant problems. These inspections could include checking for leaks in hydraulic lines or assessing tire tread wear that may impact traction on wet surfaces.

Properly maintaining your pallet truck also increases safety standards at work by preventing unexpected breakdowns or accidents due to worn-out parts. By taking care of your equipment proactively instead of reactively mitigates risks associated with operating damaged machinery.

In short, a well-maintained pallet jack ensures productivity and protects workers' safety while minimizing repair expenses in the long run.

What are some tips for maintaining your pallet jack in the rainy season?

During the rainy season, maintaining your electric pallet jack is crucial to ensure its longevity and safe operation. Here are some tips for keeping your pallet truck in top condition during wet weather.

Firstly, keep your electric pallet jack clean and dry. Wipe down the exterior of the machine after every use to remove any moisture or debris that may have accumulated on it. This will prevent rust and other damage from forming.

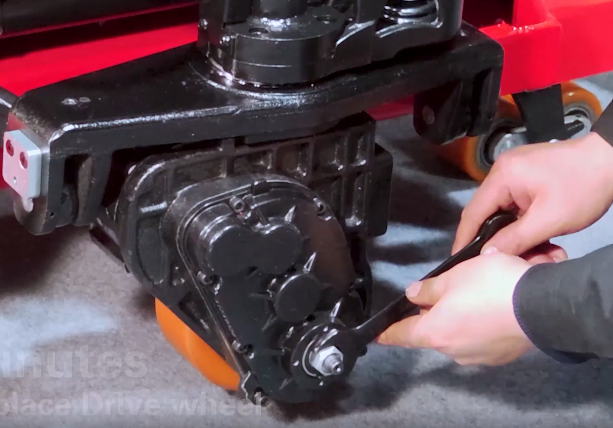

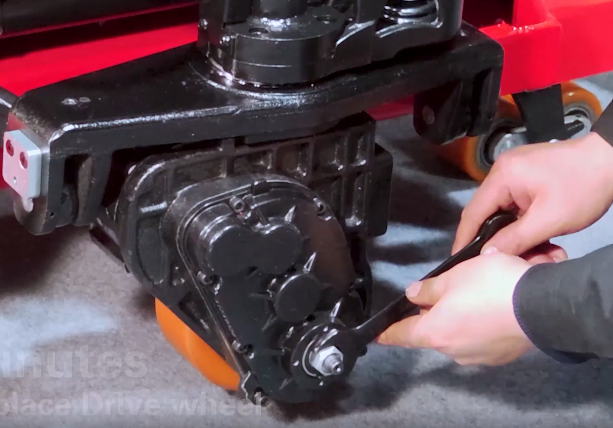

Secondly, inspect all moving parts regularly and lubricate them as necessary. The rain can cause wear and tear on these components, so it's important to keep them well-maintained.

Thirdly, make sure the wheels are free of any dirt or debris before operating your electric pallet jack. Wet conditions can increase the risk of slipping or skidding if there is anything obstructing the wheels' movement.

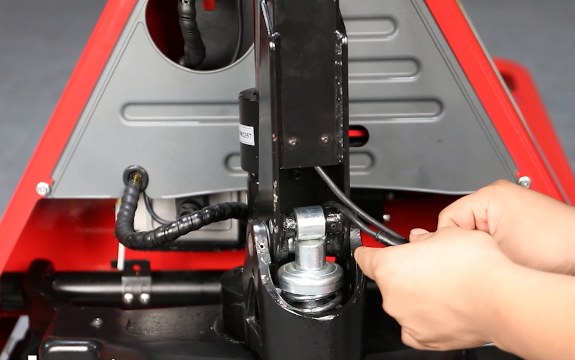

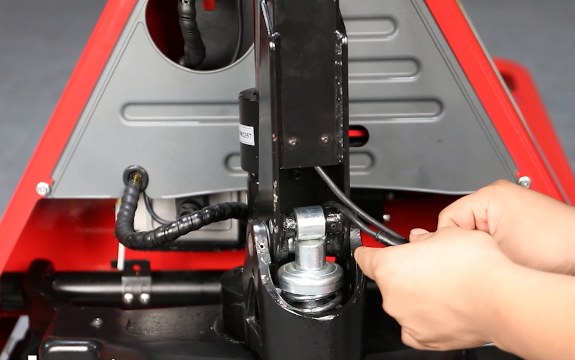

Fourthly, check that all electrical components are working correctly before using your electric pallet jack in wet weather conditions. Water can damage electrical systems quickly, so take extra care with these parts during maintenance checks.

Store your pallet truck properly when not in use during heavy rainfalls or storms. If possible, cover it with a tarpaulin or store it indoors to protect it from water damage.Regular inspections are fundamental in maintaining safe and efficient operations with a electric pallet jack during the wetter months.

What are some common problems with pallet trucks in the rainy season?

In the rainy season, electric pallet jacks are prone to various common problems that can affect their functionality and longevity. One of the most common issues experienced by pallet trucks during this period is rusting due to constant exposure to moisture.

Another issue faced by electric pallet truck owners in the rainy season is water damage. Water infiltration into electrical components such as motors and switches can cause significant damage, leading to malfunction or complete breakdown of the equipment.

Additionally, wet surfaces caused by rain can make it difficult for operators to handle and move loads using a pallet jack. This can lead to accidents resulting in damage not only to the equipment but also injuries on site.

Another problem associated with operating a pallet jack during rainy seasons is inadequate lubrication which leads to excessive wear and tear on parts such as wheels, bearings among other moving parts. This ultimately reduces its lifespan if not addressed.

Regular maintenance practices such as cleaning after use, proper storage procedures when not in use, timely inspection of all critical parts should be carried out regularly so that these problems do not negatively impact your business operations or put personnel at risk when working with them.

How to troubleshoot common problems with pallet trucks in the rainy season

When it comes to pallet jacks, rainy season presents unique challenges that can cause common problems. If you are experiencing issues with your electric pallet jack during the rainy season, here are some tips to help troubleshoot them.

Firstly, if your electric pallet jack is losing traction and slipping on wet surfaces, check the condition of its wheels. Worn or damaged wheels may need to be replaced in order for the pallet truck to operate smoothly even on wet surfaces.

Secondly, if water has entered into the electrical components of the pallet jack causing malfunctioning or non-operational controls, try drying these parts using a hair dryer before attempting any repairs. In case this does not work and you're still having issues after drying out all electrical equipment inside your pallet jack's control box/devices then have it inspected by an authorized technician.

Thirdly, if there is excessive rust forming on metal parts like forks or frame due to prolonged exposure to rainwater make sure they are cleaned properly and well dried afterwards so as not accelerate oxidation process which could lead into wear-and-tear over time resulting in shorter lifespan for those particular pieces of equipment.

Lastly but also very important, always follow manufacturer recommendations regarding maintenance schedule since improper care could result in costly damage down line when working under such harsh conditions during Rainy Season!

Conclusion

Maintaining your electric pallet jack in the rainy season is crucial to ensure its longevity and efficient performance. By following the tips mentioned above, you can avoid common problems with your pallet truck during the rainy season.

Remember to inspect your electric pallet jack regularly, especially before and after use. Look out for any signs of wear and tear, such as rust or worn-out tires. Addressing these issues promptly will prevent them from becoming more significant problems that could lead to costly repairs or replacements.

By taking proper care of your pallet jack during the rainy season, you'll not only save money but also improve workplace safety by reducing accidents caused by damaged equipment.

In summary, maintaining a pallet jack requires some effort; however, it's well worth it in the long term. With regular inspection and maintenance checks throughout the year, particularly during harsh weather conditions like rain, you can keep your equipment running smoothly for years to come.

+86-574-89217230 |

+86-574-89217230 |  info@cnmhe.com

info@cnmhe.com